Crane Safety Catches: Prevent Accidents During Heavy Lifting Operations

27 November 2024

Ensure safety during heavy lifting operations with crane safety catches from Hydromech. Understand their primary role in preventing accidents.

Heavy lifting operations often involve the use of cranes, hoists, or other equipment to lift and transport heavy loads, typically exceeding standard manual handling limits. Tasks during these operations may include installing large machinery, lifting structural components, or moving heavy materials. To prevent accidents and ensure efficient workflow during these operations, contractors should carry out proper planning, implement safety measures, and invest in safety equipment like crane safety catches.

A Quick Look at Crane Safety Catches

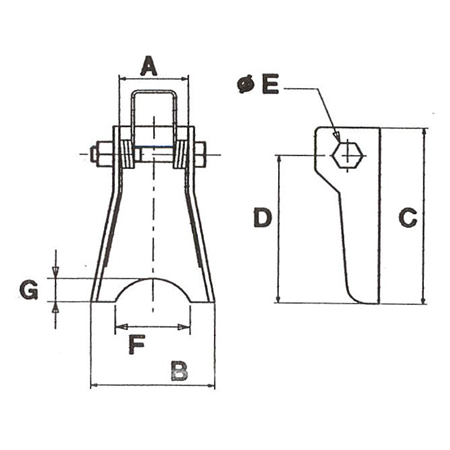

In general, crane safety catches are safety devices designed to prevent accidents during lifting operations. They work by automatically engaging when the crane is in a non-operational state, securing the load and preventing it from dropping.

These catches are typically installed on the crane’s hook or load block and function as a fail-safe mechanism, making sure that if the primary lifting mechanism fails, the load remains securely held. This improves safety for both operators and personnel in the vicinity, significantly reducing the risk of accidents during heavy lifting tasks.

Mitigating Risks During Heavy Lifting

Crane safety catches play a huge role in mitigating risks associated with heavy lifting operations by solving several key problems:

1. Load Drops: One of the most critical functions of safety catches is to secure loads if the primary lifting mechanism, such as the winch or hook, fails. This prevents the load from falling, which can lead to severe injuries or fatalities.

2. Worker Safety: The presence of safety catches significantly reduces the risk of accidents involving workers in the vicinity. When a load is properly secured, it minimises the chances of workers getting injured from falling objects.

3. Equipment Damage: Falling loads can cause substantial damage to both the equipment and the materials being handled. Crane safety catches help prevent this damage, leading to lower maintenance and replacement costs.

4. Regulation Violations: Many safety standards and regulations mandate the use of safety devices like catches on cranes. Compliance not only avoids legal repercussions but also enhances the overall safety culture within an organisation.

Investing in crane safety catches can significantly enhance the safety and efficiency of heavy lifting operations, which fosters a safer work environment.

Picking the Right Crane Safety Catches

When picking crane safety catches, you should consider the following factors:

1. Load Capacity: You must verify that the safety catch can handle the maximum weight you intend to lift. It’s crucial to select one that exceeds the weight requirements to provide an extra safety margin.

2. Compatibility: Ensure that your safety catch is compatible with your crane type and model. Not all catches fit every crane, and using an incompatible catch can compromise safety.

3. Material Quality: Choose safety catches made from robust materials, such as high-grade steel or alloy, as they can endure the stresses of heavy lifting and resist wear and tear.

4. Ease of Maintenance: Select catches designed for easy inspection and maintenance. Those that allow for straightforward maintenance will save you time and effort.

Safety Standards: Look for safety catches that adhere to local safety standards, such as AS 1418 to ensure that they meet safety and quality benchmarks.

If you need quality crane safety catches, go get them from us at Hydromech. We are a known supplier of new and innovative technology in the overhead crane and hoist industry in Australia and beyond.

Optimized by: Netwizard SEO